Predictive maintenance with telematics can save UK fleets up to 30% on repair costs and reduce breakdowns by 45%. By using real-time vehicle data, telematics predicts issues before they happen, minimising downtime and maximising efficiency. Here's how it works:

- Data Collection: Telematics gathers diagnostics like engine performance, tyre pressure, and brake wear through sensors and the OBD-II port.

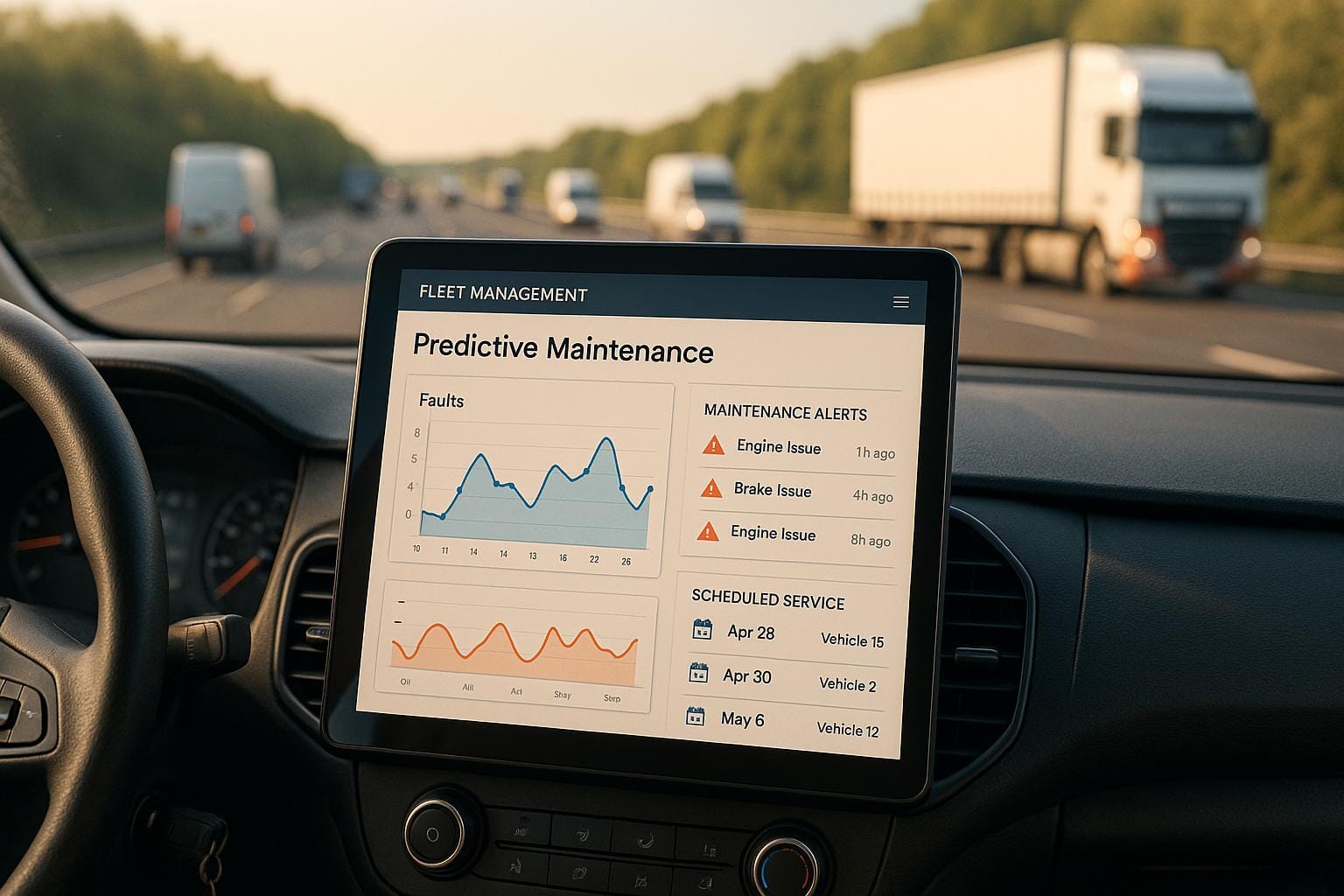

- Real-Time Analysis: Machine learning identifies anomalies, helping fleet managers act before small issues escalate.

- Automated Alerts: Maintenance schedules adapt to vehicle conditions, reducing unnecessary servicing.

- Cost and Compliance Benefits: UK fleets save on repairs, meet regulatory standards, and improve safety.

With telematics, fleets operate more efficiently, extend vehicle lifespans, and comply with evolving UK regulations. This data-driven approach is transforming fleet management.

Predictive Maintenance to Revolutionize Fleet Management

How Telematics Powers Predictive Maintenance Scheduling

Telematics has transformed vehicle maintenance by introducing a data-driven approach that predicts potential issues in real time. By turning raw vehicle data into actionable insights, it enables proactive maintenance decisions that keep fleets running smoothly.

Data Collection Through Telematics Systems

Modern telematics devices go beyond basic tracking to gather detailed diagnostics, offering a clear view of a vehicle's health. The OBD-II port plays a central role here, connecting directly to the vehicle's engine control module to capture diagnostic codes and performance metrics such as fuel usage and engine efficiency. Additional sensors provide even more detail, monitoring factors like tyre pressure, brake wear, temperature, and vibration levels, giving a well-rounded picture of the vehicle's condition.

GPS tracking adds another layer by offering real-time updates on vehicle location, engine performance, and fuel efficiency, while also flagging potential warning signs. This combination of data not only helps fleet managers track their vehicles but also understand their performance under various conditions.

Telematics systems continuously monitor vehicle health during operation, transmitting data via cellular networks to centralised management platforms. This constant data flow helps identify patterns and anomalies that traditional maintenance methods might overlook.

Real-Time Data Analysis for Predictive Insights

Once the data is collected, it undergoes real-time analysis to convert raw information into actionable insights. By comparing incoming data against established performance benchmarks for each vehicle, the system can detect anomalies that signal potential issues. This proactive approach can reduce downtime by 30–50% and cut maintenance costs by 20–40%.

Machine learning plays a key role here, analysing historical data to spot subtle changes like unusual vibration patterns, engine temperature shifts, or declining fuel efficiency. These insights ensure maintenance decisions are precise and tailored to each vehicle's unique operating conditions.

For UK fleets, this level of analysis is especially valuable, given the diverse driving environments across the country. For instance, vehicles navigating London's stop-start traffic experience different wear patterns compared to those on long motorway routes. Predictive insights adapt to these variations, enabling more effective maintenance planning.

Automated Maintenance Alerts and Scheduling

The final step in telematics-driven maintenance is turning these insights into action. Automated alerts notify fleet managers and drivers of upcoming maintenance tasks, part replacements, or document renewals based on the vehicle's actual condition rather than fixed schedules. For example, if sensors detect that brake wear is approaching safety limits, the system flags the vehicle for immediate inspection.

Scheduling tools optimise maintenance timing by factoring in vehicle availability and operational needs, ensuring tasks are carried out during off-peak hours to minimise disruption. This is crucial for UK fleets, where vehicle downtime can cost businesses between £350 and £590 per day per vehicle.

Benefits of Predictive Maintenance for UK Fleets

Cost Savings and Reduced Downtime

Predictive maintenance offers a practical way for UK fleet managers to cut costs and minimise downtime. By using preventive scheduling, fleets have reported up to 30% savings on repair bills and a 21% drop in maintenance costs. With parts prices climbing by 35% over the last four years, this approach has become a financial lifeline.

Take, for instance, a London-based courier service that managed to slash 40% off breakdown costs, or Royal Mail, which expects to save at least £50,000 annually. These savings demonstrate the value of predictive maintenance for fleets of all sizes.

This strategy doesn’t just save money - it also extends vehicle lifespans and boosts resale values. By addressing wear and tear before it leads to failure, vehicles perform more reliably throughout their operational life. This shift turns maintenance from a reactive expense into a forward-thinking investment.

Looking ahead, UK businesses are set to invest around £1.2 billion in predictive maintenance technologies by 2033. This growing trend highlights a clear focus on tackling issues before they escalate into costly problems.

Meeting UK Fleet Standards and Compliance

Beyond cost savings, predictive maintenance simplifies the challenge of meeting UK regulatory requirements. Telematics-enabled systems, for example, make it easier to comply with the DVSA Earned Recognition scheme, which tracks driver management, maintenance standards, and record-keeping automatically. This eliminates the need for time-consuming manual checks.

Such automation also monitors driver hours, vehicle diagnostics, and emissions data. This reduces administrative workloads and ensures legal compliance, which is crucial given that road accidents cost UK businesses approximately £36 billion each year. Staying compliant isn’t just about avoiding penalties - it’s also a smart financial move.

Predictive maintenance also supports fleets in meeting environmental regulations. By helping monitor emissions and align with green initiatives, telematics systems ensure fleets are prepared for evolving standards. Companies using these systems have reported a 20–30% reduction in vehicle downtime, enjoying both operational efficiency and safety benefits.

Better Fleet Efficiency and Productivity

The advantages of predictive maintenance go beyond cost-cutting - it enhances overall fleet performance. Well-maintained vehicles are more reliable, consume less fuel, and operate more efficiently. This creates a ripple effect, improving productivity and reducing expenses.

"Fleet success starts with drivers - training, telematics, and fuel-smart habits cut costs and boost vehicle longevity."

– TC Gill, BD and Innovation Officer at Roedan

Telematics plays a crucial role in this by enabling smarter routing and reducing fuel consumption. For instance, better driving habits informed by telematics data can lead to 10–15% fuel savings. Additionally, these systems automate tasks like employee record keeping and payroll management, streamlining administrative processes.

Driver behaviour also improves significantly with predictive maintenance. Over a 12-month period, users of CameraMatics reported a 37% drop in harsh braking incidents and a 42% reduction in speeding events. These changes not only enhance safety but also reduce wear and tear on vehicles.

Telematics also allows for remote diagnostics, identifying and resolving maintenance issues without the need for physical inspections. This is particularly valuable for fleets operating across the UK’s varied landscapes, where disruptions can be costly.

Incorporating truck telematics systems has led to a 15–20% reduction in operational costs. This shows how predictive maintenance doesn’t just save money - it drives meaningful improvements in fleet efficiency and productivity.

Setting Up Telematics for Predictive Maintenance: Step-by-Step Guide

Selecting the Right Telematics Hardware

Choosing the right telematics hardware is essential for effective predictive maintenance. For UK fleets, dual-tracker systems stand out, offering enhanced security with a 91% recovery rate - an important consideration for fleet operators.

When selecting hardware, focus on devices equipped with robust, multi-protocol APIs. These simplify integration and ensure compatibility with various platforms. Manufacturers like Teltonika and CalAmp are known for offering devices with reliable APIs, making them a solid choice. Additionally, ensure the hardware can maintain consistent connectivity, even in rural areas where 4G coverage may be unreliable. To future-proof your investment, opt for devices that can adapt to emerging technologies without requiring a complete overhaul. Interestingly, over 70% of fleet managers report improved performance when their hardware and software are seamlessly aligned.

UK operators might explore solutions like GRS Fleet Telematics (https://grsft.com), which offers advanced tracking systems and dual-tracker technology tailored for local needs. Once the hardware is in place, the next step is integrating it with the right software.

Connecting Software Platforms

The success of your telematics system hinges on how well the software integrates with the hardware. Without effective integration, the system risks generating excessive, unusable data rather than actionable insights. Studies show that organisations using integrated solutions can boost operational efficiency by up to 30%.

Start by assessing your existing hardware and its data formats to identify any compatibility issues. It’s crucial to confirm that both the hardware and the software support API-driven integration, as this can significantly speed up deployment. Engaging with device vendors early on can help address potential challenges and ensure a smoother rollout.

Cloud-based analytics platforms are particularly effective for processing the large volumes of data generated by telematics systems. By combining data from telematics devices and operational logs, these platforms deliver a comprehensive view of vehicle health. To avoid widespread disruptions, pilot the integration with a small subset of vehicles. This allows you to identify and resolve issues before scaling up across the entire fleet. Fleets using multi-compatible systems have reported improvements in routing accuracy of nearly 25%.

Once the software and hardware are working together seamlessly, the focus shifts to preparing your team.

Training Staff and Setting Up Processes

Introducing new technology like telematics requires that your team understands how to act on predictive alerts. Proper training and clear processes are vital to ensuring the system’s success. Both drivers and technicians need to be equipped to monitor and respond to maintenance alerts generated by the telematics system.

Appoint a supervisor familiar with your fleet and its routes to lead the training programme. This person should have access to the necessary technology and data and possess strong communication skills to conduct effective coaching sessions. It’s important to emphasise to drivers that telematics is a tool for support, not a means of punishment.

Driver training should focus on interpreting maintenance alerts, performing basic troubleshooting, and following reporting procedures. Schedule regular coaching sessions and use positive reinforcement to encourage safe driving habits that reduce vehicle wear and tear. Create an open environment where drivers feel comfortable discussing any challenges they face in meeting safety targets.

Maintenance staff and fleet managers also require in-depth training to make the most of telematics data. Key areas include understanding predictive analytics, setting maintenance thresholds, and developing response protocols for different types of alerts. Supervisors should be held accountable for regular coaching and data reviews to ensure consistent application of the programme.

Start with a small group of vehicles to refine training and processes before expanding to the entire fleet. This phased approach helps identify and address any gaps early on. Regularly review and adapt your maintenance strategies based on new insights. Don’t forget the importance of routine sensor calibration - accurate data is critical for making informed maintenance decisions and avoiding costly breakdowns.

Case Studies and Success Stories

Real-life examples show how telematics can deliver measurable improvements in predictive maintenance for UK fleets, helping operations streamline their strategies and significantly cut costs.

Urban Delivery Fleets

Urban delivery fleets often face challenges like constant stops, heavy traffic, and intensive vehicle use. For instance, HATS Group deployed telematics across its 880-vehicle fleet and saw remarkable results: road incidents dropped by 78%, while related costs plummeted by 96%. By combining advanced telematics with dash cameras, this healthcare transport operator not only improved safety but also revolutionised its maintenance practices.

DPD Local also embraced predictive maintenance across its urban delivery network. This approach reduced emergency callouts by 25% and ensured better vehicle availability during peak delivery times. By scheduling maintenance around delivery routes, they minimised disruptions without compromising service quality.

While urban fleets reap the benefits of reduced incidents and better-targeted maintenance, long-haul operations face a different set of challenges.

Long-Haul Transport Fleets

Long-haul fleets, which cover vast distances and encounter diverse conditions, have also seen success with telematics. In March 2025, SIXT van & truck collaborated with a leading telematics provider to enhance its UK commercial vehicle rental fleet. A pilot programme not only recovered two stolen vehicles but also utilised OEM data for predictive maintenance, ensuring contracts were met and vehicle performance improved.

United Utilities adopted an integrated telematics system that enhanced fleet sustainability, boosted driver safety, and improved vehicle availability. Their system also increased operational efficiency and cut emissions. Similarly, SUEZ applied telematics to its waste collection trucks, achieving a 20% reduction in repair costs.

Keith Elkington Transport leveraged a telematics solution to provide real-time feedback on driving performance and monitor harsh driving behaviours. This contributed to better efficiency and overall operational improvements.

These examples highlight how telematics is transforming predictive maintenance, enhancing fleet performance, and extending vehicle lifespans across various UK sectors. At GRS Fleet Telematics (https://grsft.com), we are dedicated to offering advanced van tracking solutions that help UK fleets unlock telematics' full potential - boosting efficiency, cutting downtime, and improving overall performance.

Conclusion: The Future of Predictive Maintenance with Telematics

Telematics has transformed fleet management in the UK, shifting the focus from reactive repairs to proactive, data-driven maintenance strategies. The results speak for themselves: fleets using telematics-powered predictive maintenance have seen a 30% drop in unplanned downtime and a 20% reduction in repair costs. These advancements are paving the way for a new era in fleet management.

The rapid development of 5G and AI is pushing telematics to new heights. AI processes real-time data to predict maintenance needs with remarkable precision, while 5G ensures faster, more responsive communication. Together, these technologies are not only enhancing current maintenance systems but also driving growth in the sector. For instance, the global fleet management market is expected to reach £58.8 billion by 2028, and AI in transportation is projected to grow to £18 billion by 2032.

"With in-cab alerts and AI-enabled dashcams, it now intervenes in real-time to address issues such as distracted driving or driver fatigue", says Philip van der Wilt, vice-president for Europe, the Middle East and Africa at Samsara.

UK businesses are already adopting these technologies, with 45% of leaders currently leveraging AI and 89% planning to increase investments in the next year. This momentum aligns perfectly with the approaching 2030 ban on new petrol and diesel vehicles in the UK. Telematics will play a crucial role in managing the transition to electric fleets, ensuring compliance with evolving regulations.

The long-term advantages are clear: 24% lower fuel costs, 20% reduced insurance premiums, and 16% savings on maintenance expenses. These savings accumulate over time, providing fleet operators with a competitive edge through improved efficiency and reduced operational costs.

For businesses looking to embrace these advancements, GRS Fleet Telematics offers cutting-edge van tracking solutions starting at just £7.99 per month. With a 91% recovery rate and dual-tracker technology, GRS goes beyond simple tracking to safeguard your assets and prepare your operations for the digital future. These solutions highlight how the innovations discussed in this guide can be practically applied to enhance fleet performance and protect your investment. For more details, visit GRS Fleet Telematics.

FAQs

How does telematics help identify maintenance needs before they become major issues?

Telematics technology plays a crucial role in keeping vehicles in top condition by constantly monitoring their performance and analysing real-time data. It keeps an eye on essential metrics like engine health, fuel consumption, and driving habits, making it easier for fleet managers to detect issues before they turn into major problems.

For instance, telematics systems can issue alerts when a vehicle is approaching its next service interval or if any unusual performance trends are spotted. This kind of proactive maintenance helps prevent unexpected breakdowns, keeps repair costs in check, and reduces downtime. By tapping into detailed data insights, telematics ensures fleets run more smoothly and efficiently.

How can telematics help UK fleets save money and improve efficiency with predictive maintenance?

Telematics is transforming the way UK fleets manage costs and efficiency, particularly through predictive maintenance. By leveraging real-time data and analytics, telematics systems can pinpoint potential problems before they escalate into expensive breakdowns. This not only cuts down on unplanned repair bills but also keeps vehicles on the road, reducing downtime.

On top of that, telematics plays a key role in cutting fuel expenses. It helps streamline route planning, minimise idling, and promote fuel-efficient driving behaviours. The result? Fleets can save thousands of pounds each year. Together, these advantages enhance fleet performance and lower the overall cost of ownership.

How does telematics-based predictive maintenance help UK fleets meet regulations and environmental goals?

Telematics-based predictive maintenance is proving invaluable for UK fleets, helping them stay on top of regulations while contributing to environmental goals. By delivering real-time data on vehicle performance, these systems keep a close eye on critical metrics like engine health and fuel efficiency. They alert fleet managers to potential problems early, preventing expensive breakdowns and ensuring vehicles remain safe and compliant with emissions standards.

Beyond maintenance, telematics plays a key role in reducing carbon footprints. By streamlining routes, boosting fuel efficiency, and promoting eco-conscious driving habits, these systems help fleets minimise environmental impact. This approach not only supports green initiatives but also improves day-to-day operations, making it easier for businesses to adapt to the UK's ever-changing sustainability and compliance demands.